rockwell hardness test steps|rockwell hardness tester procedure pdf : factories In the Rockwell hardness test, an indenter is pressed into the material to be tested. The indentation depth serves as a measure of the hardness! The measuring process of the Rockwell test is carried out in three .

web13 de nov. de 2023 · Recentemente, a 000 Bet tem despertado o interesse de muitos .

{plog:ftitle_list}

webDark Periscope Link. 23.6K members. РЕЗЕРВ: По всем вопросам писать - @visualdrop. Open a Channel via Telegram app. Preview channel. Don't have Telegram yet? Open via web telegram. or. Get telegram app.

The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the Rockwell .

In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors .

The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth .Rockwell Hardness Test Procedure: A Step-by-Step Guide. How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? Interpreting the Results with a Rockwell Hardness Test Chart. How to .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. In the Rockwell hardness test, an indenter is pressed into the material to be tested. The indentation depth serves as a measure of the hardness! The measuring process of the Rockwell test is carried out in three .

rockwell hardness testing procedure pdf

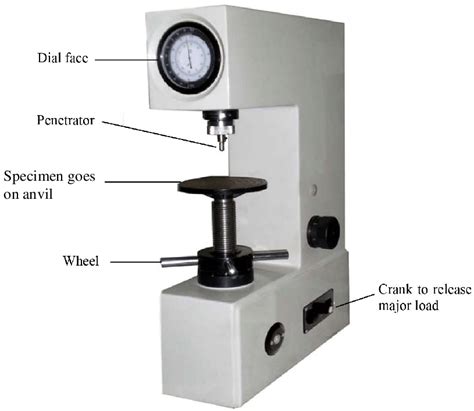

Principle of Test. The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a .

The Rockwell hardness test is a measuring system used to determine how resistant a material is to another object. Grab this complete guide.Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .

The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice.What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared .

rockwell hardness tester procedure pdf

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for .

The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. . Rockwell hardness testing involves indenting a material with either a diamond or steel ball indenter under a minor preload and then a major load. The difference in indentation depth is used to determine the Rockwell hardness number on various scales. There are 30 Rockwell scales that use different indenters and loads.

rockwell hardness tester manual pdf

The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on . In the third step, the force is returned to the previous force. After a certain holding time, the hardness value can be read from the hardness tester.The Rockwell Hardness Test is one of several tests used to determine whether a material is solid and durable enough to be employed as a component of an object. The Knoop, Brinell, and Vickers procedures are additional examinations in the sequence. . STEP 01 . Share Your Testing Material Details with Us. STEP 02 . Hassle-Free Collection Pick .

The Rockwell hardness test method, as properly defined in ASTM E-18 standards, is the most commonly used hardness test method among all the other methods. + 86 755 61301520; . Applying a preliminary small load or force often called a minor load is the first step. You apply this minor load with the use of a diamond indenter or sometimes a ball .The Rockwell hardness test is an essential tool in material science, offering a fast and trustworthy way to measure how hard materials are, with a special focus on metals. . Steps: 1. Scale selection: It is very important to choose the Rockwell scale that matches the material’s type and required hardness.

Steps for The Test 3.1 Sample Preparation. To ensure accurate results, the test surface must be flat, smooth, and free from contaminants. . For the Rockwell Hardness Test, the Indenter is a Small Steel Ball (HRB) or a diamond cone (HRC) Hardness greater than 650 HB can not be measured with the Brinell Scale setup.

The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard carbon steels. .🕑 Reading time: 1 minute Hardness of a material is defined as its resistance to indentation. Rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness scale is designed to determine the [.]Here's a step-by-step instruction to guide you through a standard hardness testing procedure, in this case, we'll use the commonly used Rockwell hardness testing method as our guide: Selection of an appropriate scale: Different testing scales (e.g., Rockwell B or C, etc.) are designed for materials of varying hardness.The Rockwell hardness test continues to be applied as a tool for assessing the properties of a product while the tolerances on the acceptable material . calibrations is a beneficial step to reducing measurement errors. The purpose of this Guide is to explain the causes of variability in Rockwell hardness test

Rockwell hardness testing can determine the hardness of most metals, alloys and plastics, ranging from the softest bearing materials to the hardest steels. Photo: Wilson Instruments, An Instron Company . Following .Rockwell Hardness Test Procedure: A Step-by-Step Guide. The Rockwell hardness test is a standardized method used to measure the hardness of materials. It provides valuable information about a material's resistance to .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics. . The procedure of the Rockwell hardness test consists of the following steps .

rockwell hardness tester instruction manual

The Rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the Rockwell formula. The resulting value is then translated to the Rockwell C scale of hardness to determine the hardness of the material. . Understanding Rockwell hardness is a critical step in understanding the properties of .Rockwell Hardness Test Procedure. We will discuss all the steps one by one to make it easy for you. Step 1: In the very first step you have to apply a minor load (f0) on the indenter.

Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to .

The 3 steps of Rockwell hardness testing The indenter is first pressed into the surface of the specimen with a specific preload F 0 . This is to exclude influences of the surface on the hardness value, such as scale layers, hardenings, etc.The Rockwell Hardness Test. The Rockwell is a widely accepted method for both soft and hard metals. This system gauges malleability by measuring the depth a pointed probe known shape and size will penetrate into the material given an exact amount of force upon it. . The two step Rockwell test: Step 1. Calibrate Load. The test object is set .Rockwell hardness test are illustrated in Fig. 1 (diamond indenter) and Fig. 2 (ball indenters) and the accompanying Table 1 and Table 2. In the case of the Rockwell superficial test . forced into the surface of a test piece in two steps under 6 Annual Book of ASTM Standards, Vol 03.01. 7 Annual Book of ASTM Standards, .

The Rockwell hardness test continues to be applied as a tool for assessing the properties of a product while the tolerances on the acceptable material . calibrations is a beneficial step to reducing measurement errors. The purpose of this Guide is to explain the causes of variability in Rockwell hardness test The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting indentation, which indicates the material’s hardness. Here’s a step-by-step of the process: Apply preliminary load. Start by applying a minor load of 10 kgf to the material.

rockwell hardness tester chart

rockwell hardness test calculation

webDoujin | MILFs & Mom is priority 3.4K members. Thanks To: @nhentai::::: Other Channel: @moehen 🏩 NiiHen Corp. Open a Channel via Telegram app; Preview channel. Don't have Telegram yet? Open via web telegram

rockwell hardness test steps|rockwell hardness tester procedure pdf